|

Ningbo Bonwin Magnet Co., Ltd.

|

Epoxy coating

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Epoxy coating

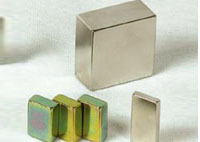

1)Composite: Neodymium Magnet

2)Coatings of magnets: Zn, Ni, epoxy

3)High grade can be used

Epoxy coating

Arc magnet coating Zn

Name: Neodymium Magnet

Grade: N35-N52, 35H-48H,30SH-45SH,28UH-40UH,28EH-38EH,ETC

Shape: Block, Ring, Disc, Ball, Sheet and so on

Short Lead Time :10-18days

Key Advantages:

Applications:

- Neodymium magnets are the most powerful commercially produced magnets.

- NdFeB magnets have a higher Maximum Energy Product, (BH).max, which can easily reach 30 MGOe and even goes up to 50 MGOe.

- NdFeB magnets can replace SmCo magnets in most cases, especially where operating temperature is less than 80 degrees Centigrade.

- Very high strength.

- Relatively low cost.

- Compared to Alnico and SmCo magnets, relatively easy to machine.

Common Applications :

Sensors Linear actuators Microphone assemblies Magnetic separators DC and servo motors Speakers Printers Magnetic hooksComputer rigid disc drives Beam controls Intelligent toys MRI/NMR Electric component

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Epoxy Coating Magnets

Pure Epoxy Powder Coating

Epoxy-Polyester Powder Coating

Epoxy

Epoxy Magnets

Epoxy Ndfeb Magnet

More>>