|

Ningbo Bonwin Magnet Co., Ltd.

|

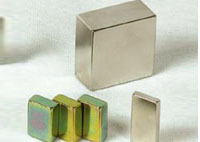

sintered ALNICO magnet with Ni coating

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Performance: well performance in temperature stability

Processing: various sizes and shapes.

Introduction

sintered ALNICO magnet with Ni coating

Production: costing and powder metallurgy

Constitution: Al-Ni-Fe-Co

Performance: well performance in temperature stability

Processing: various sizes and shapes.

Application: Applied in instruments and other like fields..

4. Alnico magnets

The name of Alnico magnets comes from its main compositions—Al, Ni, Co. They are made through casting and sintered. They are inexpensive and have wide temperature stability. Thus, compared to other permanent magnet materials, they have such obvious advantages as bellow:

1. solid and breakable

AiNiCo magnets

In the 1930s, early permanent AlNiCo magnets came into being and predominated over the permanent magnetic material due to its excellent properties. AlNico magnet is a kind of alloy formed by Al, Ni, Co and other trace elements. Its function and magnetic performance vary because of different compositions of metals. There are two kinds of production, costing and sintered. Through costing, magnets can be manufactured into various sizes and shapes. But sintered is suitable for making small size of magnets. The dimensional tolerance of blanks by sintered is better and more workable than that by costing, but the magnetic properties are slightly lower than costing products. Among the magnetic materials, AlNiCo magnets have the lowest reversible temperature coefficient, and its working temperature is up to 600 ℃. AlNiCo magnets are commonly applied in all kinds of instrumentations and other fields.

Advantages:

1. High Frequency Induction Melting Technology. Our raw materials are in accordance with the standards of International Environmental Protection Organization (IEPO) and ROHS

2. A high standard of gold finishing techniques. The minimum tolerance can be ±0.01mm.

3. Thermal control of the directional columnar crystal ingot Technology.

4. Automatic Heating Equipment to make sure consistency of magnet properties.

5. Laboratory of Physics and Chemistry for studying the relation between AlNiCo properties and its constitution and developing new kind of magnets by using new achievements in scientific research.

sintered ALNICO magnet with Ni coating

Production: costing and powder metallurgy

Constitution: Al-Ni-Fe-Co

Performance: well performance in temperature stability

Processing: various sizes and shapes.

Application: Applied in instruments and other like fields..

4. Alnico magnets

The name of Alnico magnets comes from its main compositions—Al, Ni, Co. They are made through casting and sintered. They are inexpensive and have wide temperature stability. Thus, compared to other permanent magnet materials, they have such obvious advantages as bellow:

1. solid and breakable

AiNiCo magnets

In the 1930s, early permanent AlNiCo magnets came into being and predominated over the permanent magnetic material due to its excellent properties. AlNico magnet is a kind of alloy formed by Al, Ni, Co and other trace elements. Its function and magnetic performance vary because of different compositions of metals. There are two kinds of production, costing and sintered. Through costing, magnets can be manufactured into various sizes and shapes. But sintered is suitable for making small size of magnets. The dimensional tolerance of blanks by sintered is better and more workable than that by costing, but the magnetic properties are slightly lower than costing products. Among the magnetic materials, AlNiCo magnets have the lowest reversible temperature coefficient, and its working temperature is up to 600 ℃. AlNiCo magnets are commonly applied in all kinds of instrumentations and other fields.

Advantages:

1. High Frequency Induction Melting Technology. Our raw materials are in accordance with the standards of International Environmental Protection Organization (IEPO) and ROHS

2. A high standard of gold finishing techniques. The minimum tolerance can be ±0.01mm.

3. Thermal control of the directional columnar crystal ingot Technology.

4. Automatic Heating Equipment to make sure consistency of magnet properties.

5. Laboratory of Physics and Chemistry for studying the relation between AlNiCo properties and its constitution and developing new kind of magnets by using new achievements in scientific research.

Process flow sheet

sintered AlNiCo

Raw materials → ingredients → magnetic powdering → pressing →sintered → heating → magnets test → → products test → packing

sintered AlNiCo

Raw materials → ingredients → magnetic powdering → pressing →sintered → heating → magnets test → → products test → packing

Costing AlNiCo

Raw materials → ingredients → melting → costing → heating → magnets test → → products test → packing

Raw materials → ingredients → melting → costing → heating → magnets test → → products test → packing

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Sintered Alnico Magnet

Sintered Alnico

AlNiCo Magnet

Sintered Magnet

Cast Alnico Magnet

Alnico Ring Magnet

More>>