|

Ningbo Bonwin Magnet Co., Ltd.

|

different types magnet

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

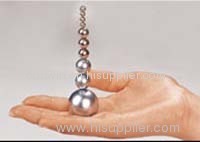

Magnet sphere

1.Certification:ISO9001:2008

2.Materials: NdFeB

3.Coating:Paint,Ni,Zn,etc

4.Grade:N33-52,M,H,SH,UH,EH

Magnet sphere

1. Materials of the Ball magnets: Neodymium-Iron-Boron;

2. Technology: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

3. Magnetic properties: High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature;

4. Grades: N33-,33M-48M,33H-48H,30SH-45SH,30UH-38UH and 30EH-35EH;

5. Shapes and sizes: Various kinds or according to customers' request;

6. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene and so on;

7. Applications of magnet: Widely used in different applications, such as toys, jewelry, gifts, bracelet, sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on. The Magnet sphere are widely used as toys, gifts, jewelry.

Magnetic sphere are used in packing, motors, golf, medical treatments, magnetic suspension, magnetic separator, crushers machine, pipe descaling, magnetic fixture, iron scrap dividing machines, magnetic suckers, fasteners, tiles, one-sided magnets, magnets for teaching, loudspeakers, portfolio, gifts, toys, magnetite straining, lifting motors, rubber magnets, magnetic cores, fridges, magnetic hasps, magnetic locks, windows, bags, doors, magnets of high temperature resistance.

Raw magnets

1. NdFeB, SmCo, Ferrite, AlNiCo magnets of various sizes and shapes. They can be discos, blocks, rings and tegular shaped, as well as customized by clients.

Besides, our technicians can help design products according to magnetic application of clients.

2. Application-specific magnets

Ferrite NdFeB magnets of high remanence(Br) for high-end speakers and microphones, tegular-shaped magnets for motors, magnets for drum motors, large sized suckers, health care equipments, sensors, toys, nuclear magnetic resonance, refrigerator door seals.

3. Magnetic assemblies

There are all kinds of magnetic assemblies for positioning, hanging, rotating, e.g. compasses, hook assemblies, steel cup assemblies, and whiteboard suctions. Except for standard products, we can also manufacture special products on customers' requirements.

Magnetic sphere are used in packing, motors, golf, medical treatments, magnetic suspension, magnetic separator, crushers machine, pipe descaling, magnetic fixture, iron scrap dividing machines, magnetic suckers, fasteners, tiles, one-sided magnets, magnets for teaching, loudspeakers, portfolio, gifts, toys, magnetite straining, lifting motors, rubber magnets, magnetic cores, fridges, magnetic hasps, magnetic locks, windows, bags, doors, magnets of high temperature resistance.

Raw magnets

1. NdFeB, SmCo, Ferrite, AlNiCo magnets of various sizes and shapes. They can be discos, blocks, rings and tegular shaped, as well as customized by clients.

Besides, our technicians can help design products according to magnetic application of clients.

2. Application-specific magnets

Ferrite NdFeB magnets of high remanence(Br) for high-end speakers and microphones, tegular-shaped magnets for motors, magnets for drum motors, large sized suckers, health care equipments, sensors, toys, nuclear magnetic resonance, refrigerator door seals.

3. Magnetic assemblies

There are all kinds of magnetic assemblies for positioning, hanging, rotating, e.g. compasses, hook assemblies, steel cup assemblies, and whiteboard suctions. Except for standard products, we can also manufacture special products on customers' requirements.

2. poor anti-demagnetization

3. good thermal stability

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!